Highly Efficient Façades with Innovative Shading and Light Control

Harvard University SEC Complex of the John A. Paulson School of Engineering

Presented on October 13, 2022 at Facade Tectonics 2022 World Congress

Sign in and Register

Create an Account

Overview

Abstract

The Science and Engineering Complex (SEC) on the Allston Campus is the largest new building at Harvard University in recent decades with a footprint of 544,000 sq.ft. which stretch nearly 500 ft. along Western Avenue.

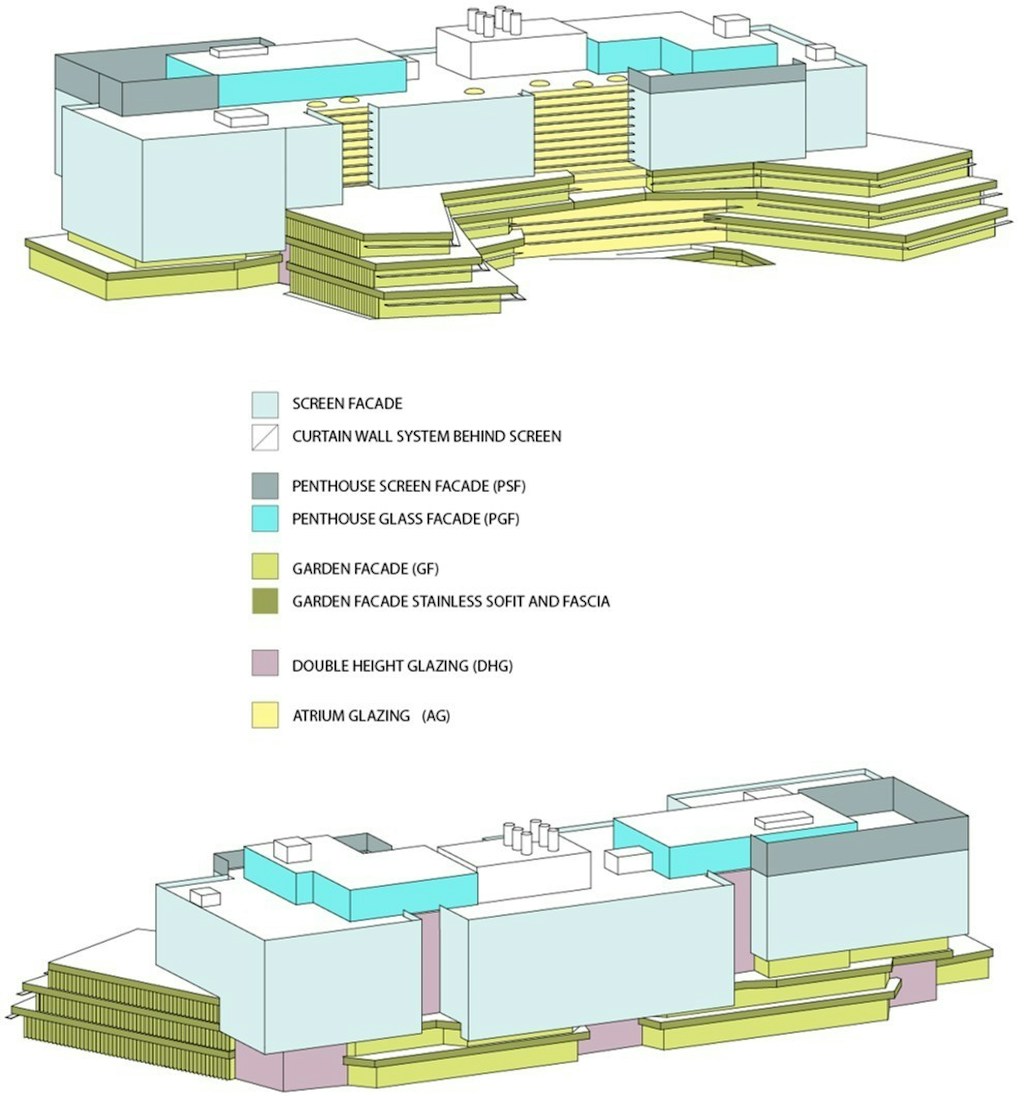

Josef Gartner USA, a division of Permasteelisa North America Corp., provided a mix of 6 different facade types to clad 262,000 sq. ft. of exterior surface.

This includes, steel stick system facades with both rectangular steel hollow sections and welded steel T-profiles at the main and entrance facades.

A 60 ft. height Atrium facades suspended off a ¾ in. x 2 3/8 in. steel flat is structurally stabilized for wind loads with exterior stainless steel clad shading screens.

Both manual and motorized windows in the Garden Facade as well as motorized lamella windows in the Atriums provide natural ventilation and serve as the smoke-evacuation system.

The unique Screen System Facade includes innovative solar control panels. At the double skin like facade, pre-stressed tension rods hold 12,900 hydro-formed stainless steel panels. Hydroforming is common in the production of components for the food and automotive industries and was used here for the first time in facade construction. This world's first hydro-formed facade system offered the architects more design options, including organic shapes.

Those stainless screen panels, horizontal shading panels as well as triple-glazed insulated glass with solar control and heat insulation coating contribute to the SEC's heat transfer coefficient of less than 0.158 Btu/(h-sq.ft.˚F).

It has been named one of the world´s healthiest and most energy-efficient laboratory buildings and certified with LEED Platinum. The SEC is the largest building and first wet laboratory building to achieve the International Living Future Institute’s Living Building Challenge Petal certification.

Authors

Klaus Reuschle

Project Director

Josef Gartner USA, a Division of Permasteelisa North America

k.reuschle@permasteelisagroup.com

Robert Matthew Noblett

Partner

Behnish Architekten

rmn@behnisch.com

Michelle Siu-Ching Lee

Behnish Architekten

research@behnisch.com

Roman Schieber

Associate Director ppa.

Knippers Helbig GmbH

rs@knippershelbig.com

Keywords

cable facade, double-skin, energy modeling, facade, facade analysis, facade performance, high-performance facade, innovative facades, innovative or unique, metal facade, steel facades, stick curtainwall, tensile facade, unitized curtainwall, ventilated, building performance, daylighting-glare-shading, energy efficiency, performance-based design, thermal performance, sustainability, aluminum, glass, metal, LEED, pre-fabrication

1. Introduction

The Science and Engineering Complex (SEC) is the largest and most technologically advanced building at Harvard University. The complex is situated at the Allston Campus and extends nearly 500 ft. along the Western Avenue in Boston. The building accommodates various fields of engineering sciences on a floor space of around 544,000 sq. ft. It comprises a variety of state-of-the-art labs, training, and seminar rooms that will foster meeting various intended purposes.

Behnisch Architekten (the architect of record) designed the building. Together with knippershelbig GmbH (the facade engineer), they developed unique concepts for different facade types in the project’s early phase. During the Design Assist Phase, the two collaborated with Turner Construction (the contracts manager) and Josef Gartner (the facade specialist) in creating and refining the individual facade types to cover the elevations of the complex. It was the smooth cross-border communication between these parties, characterized by a strong German-American component, that made it possible to realize numerous new technical advancements in construction. This cooperation resulted in the design of the unique and different facade systems that clad different elevations around the structure with a touch of elegance and efficiency.

The eight-floor building is divided into three portions arranged around two light-flooded atriums. Highly transparent glass ribbon windows in the base open the building up to the outside environment. Deep overhangs combined with perforated metal light shelves shade these areas and direct daylight deep into the interior of the building. Above this transparent base, the four-story research boxes seem to virtually float, lending the building a special lightness. The laboratories are arranged in these research boxes, cladded with unique stainless-steel sheets for shading. The shades convey a uniform appearance, they also shield the rooms from solar heat in the warmer months, while allowing solar radiation in winter when the sun is lower, thus reducing the cooling and heating load.

Vertically, the six above-ground levels and the two below-ground levels are connected by a central atrium that provides all floors with daylight and fresh air. This atrium is the center of social and interdisciplinary interactions that also serves as events venue. There are other smaller atriums in individual areas of the building that serve the same functions. In addition, lounge zones that open up over several floors connect the individual laboratory areas with each other and serve as meeting spaces and lounging areas. The atriums and lounge zones in the complex bring the different sections of the building together helping it to meet its social functionality.

Almost all rooms with workstations are oriented towards the facade which allows people to interact with the outside when working in the inside. All offices and meeting rooms have operable windows that allow fresh air to cascade deep into the building. These windows also allow the occupants to interact with the external environment. Different unique facade that covers various faces of the building gives it a unique look and also promotes the building’s environmental sustainability function. The design and implementation of highly efficient facades with innovative shading and light control at Harvard University’s newly developed complex, introduces the construction world to advanced methods in controlling and shading light in buildings while ensuring environmental sustainability and functional effectiveness.

2. The Garden Facade

The lower two floors of the building, and all of the terraced portions from level 1 to level 3 of the building have highly transparent, one-story glass ribbon windows that

Access Restricted

3. The Atrium Facade

The Atrium Facade is a unique and fully-custom system. The system clads the two south-facing atriums opening towards the yard between the laboratory blocks. The six-story wall of the main

Access Restricted

4. The Laboratory Screen Wall

The research lab areas are located from level 3 to 6 in the building. The areas are clad with an 81,970 sq. ft. steel stick system facade with rectangular steel

Access Restricted

5. Hydro-formed Exterior Sun Shading System

Very early in the project, Josef Gartner introduced hydro-formed stainless-steel sheets as a special proposal for the main shading system of the building. Originally the approximately 12,900 1.5mm (16 gauge)

Access Restricted

6. External Fixed Shades as Part of the Environmental Strategy

To comply with the very high energy goals of the project, the facade had to contribute to the sustainability concept. The design team developed a strategy with external fixed shade

Access Restricted

7. Conclusion

With its innovative solar control and shading devices, the building reduces CO2 emissions by up to 50% compared with similar buildings in this category. A key factor here is the

Access Restricted

Acknowledgements

Behnisch Architekten, Boston MA

knippershelbig GmbH, Stuttgart Germany

Josef Gartner USA, a division of Permasteelisa North America, Chicago IL

Josef Gartner GmbH, Gundelfingen Germany

Edelstahlmechanik GmbH, Goeppingen Germany

The President and Fellows of Harvard College, Cambridge MA | Harvard Capital Projects

Turner Construction Company, Boston MA