For more information contact Bill Pottle, Director of Business Development at Boston Valley Terra Cotta

Observations on Collaborative Process and Materiality from the Architectural Ceramic Assemblies Workshop

At the second annual Architectural Ceramic Assemblies Workshop (ACAW), participants in the architectural industry explored the prototyping and assembly of terra cotta systems through manufacturer-supported hands-on research.

Boston Valley Terra Cotta and the University at Buffalo School of Architecture and Planning, supported by the UB Sustainable Manufacturing and Advanced Robotic Technologies held the ACAWorkshop, a weeklong event developed to instruct architects, designers, and facade engineers about the manufacturing of architectural ceramics and advance the design of facade solutions.

In August, four teams of industry experts gathered in the Boston Valley plant with the goal to introduce and consider the material properties of terra cotta earlier in the design process, and to develop research and design models between manufacturing and architectural industries useful to the efficient production of facade solutions. The workshop was developed as an interdisciplinary model for design for large-scale production of ceramic assemblies; methods of study varied from research and experimentation, to modeling, rapid prototyping and construction. Representatives from the building industry – architects, designers and engineers (the visionaries) – academia (the mentors) – and manufacturing/ceramic artists (the makers) collaborated in an exploratory environment focused on learning and exploring the bioclimatic function of terra cotta facades.

Teams were comprised of a variety of members from the architectural industry: architects, facade engineers and ceramic artists alternately guided the development of the solutions, contributing their knowledge and experience. Boston Valley Terra Cotta manufacturers educated the team members about the design and manufacturing of architectural ceramics and guided the production of the proposed solutions. UB students and Alfred University students were assigned to each team to assist in the research, inform the production, and help in the presentation of the team’s solutions. Given to the collaborative nature of the workshop, workshop roles were fluid. Manufacturers became teachers about the history and production of terra cotta, designers and academics eschewed traditional models of study to include rapid prototyping in their design process. Students tasked with the role of team helpers, assisting in the construction, production and presentation of solutions developed new patterns in their design process, benefiting from lessons and expertise from architects, engineers and designers about materiality and its significance in the formation of facade solutions.

Flavio Borrelli, Architect and Ceramic Artist on Team AECOM summed up the ACAWorkshop as a “very inspiring and learning experience where participants are provided with space, tools and resources to step out of the common practice, reach out into the unknown and feed their imagination with what is possible.”

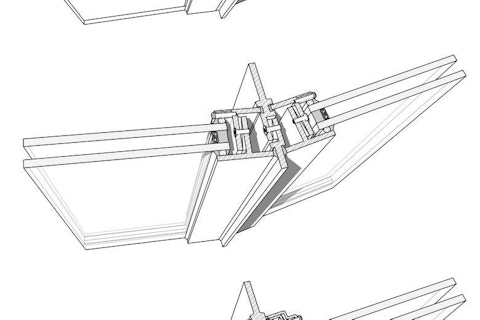

Bioclimatic studies and facade solutions varied from team to team. Team AECOM members explored the relationship between ornament and function in the materiality of terra cotta. Team members designed terra cotta envelope components in a unitized system that functions as a counter-current heat exchanger. By questioning the reason for ornamentation, the team explored the articulation of form to connect the interior and exterior walls and enhance functionality of the system. Studies tested the effectiveness of clay in the function of heat exchange with the goal of developing an attractive and cost effective system suitable for large-scale production.

The hands-on experience was invaluable, “ noted Irene Martin, Senior Building Envelope Physicist of Arup. “Boston Valley Terra Cotta and the University of Buffalo brought together a diverse group of professionals who were fully immersed in the world of architectural ceramics for the duration of the workshop.”

Irene was on Team Morphosis, which focused on the development of ceramic panels in a kinetic facade system for a climate that requires high thermal conductivity and low thermal expansion. Design of the speculative facade looked at a building’s ability to respond to its environment and the transfer of heat through solar shading and evaporative cooling. The team also studied throughbody color and the chemical clay formula’s impact on heat exchange. Challenges included the potential methodologies of construction in the efficient production of continuous geometries in a single extrusion and surface modification as well as the development of an attachment system to erect highly variable panels with necessary on site adjustments.

Team Walter P Moore designed and developed modular terra cotta units for use in a post-tensioned system. The team investigated adapting the clay mix to enhance the compressive structure of the material and the addition of composites to increase structural qualities without eliminating the aesthetic properties of terra cotta. Slip cast and wood prototype units were manufactured and studied for aesthetic and structural considerations, to populate the modules in a variable patterns and unitizing options.

Team University at Buffalo and Alfred University explored ornament on a systemic scale, designing and developing three ceramic facade systems – 2 shingle units and one screen system – that consider the bioclimatic functions of sun and shading, airflow, seasonal and evaporative cooling. The screen system studied light and illumination, while the shingle systems included a flip tile form designed for evaporative cooling and heat transfer. The team also explored the variable effects of color, glaze and patterning in development of the systems.

Planning for the 3rd ACAWorkshop, scheduled for August 13 – 17, 2018, is underway as Boston Valley Terra Cotta and the University at Buffalo are preparing to invite interested architects, designers and engineers to participate in the next evolution of the study.

All photos courtesy of OtherWisz Creative.

Looking for something specific?

Search our extensive library.

FTI’s SKINS email is the central source for the latest in building skin trends and research.

All emails include an unsubscribe link. You may opt out at any time. See our privacy policy.