In pursuit of nothing: Leveraging the facade system for net-zero-carbon

Hello! In this edition of SKINS, we’re expanding on the themes of our January issue by taking a broader view of how façades impact both operational and embodied carbon in buildings. In other words, not just looking at materials but also the design process itself. Today’s demanding performance requirements and ambitious sustainability targets call for unprecedented levels of complexity and functionality in building skins. Traditional design methods simply can’t handle the holistic consideration of the complex—and often conflicting—relationships between design variables. Designers must evolve to provide faster and more effective solutions to increasingly complex and ambiguous problems as we approach major global sustainability milestones.

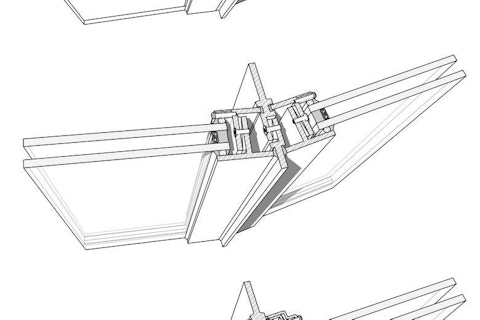

The role of the building skin in carbon performance is well understood, but not widely recognized in the building industry and it’s worth revisiting some key figures. The construction industry is responsible for about 40% of annual global greenhouse gas emissions, with cities accounting for over 70% of global emissions—construction being a primary culprit. Building skins influence roughly 50% of a building’s energy performance and account for about 20% of its embodied carbon. In this context, every dollar invested in a facade’s design and planning has an outsize impact on a building’s operational carbon and proportionally affects its embodied carbon.

Designers today face complex design problems with often conflicting performance objectives. Balancing cost, thermal behavior, acoustics, air infiltration, daylighting, aesthetics, and myriad other performance considerations that converge at the building skin, is already challenging without adding carbon counting, which penalizes every kilogram of material used. Then, consider factors like climate change, severe weather events, durability and service life, life cycle considerations, and the often-overlooked health and well-being of the user. Navigating these complexities to achieve a truly resilient and sustainable building can be a daunting task.

This complex and often contradictory network of relationships between variables doesn’t fit a traditional linear approach to building design. Recognizing this, international organizations have published manuals and standards, such as TM65 from CIBSE, to provide a common framework for addressing these issues. Efforts to understand the carbon footprint of complex manufactured products, like unitized Curtain Walls, have also been significant, highlighting the importance of taking into account the supply chain carbon implications for each component. Good information is crucial; material, product, and supplier selection can have an enormous impact on a project’s carbon budget.

With solid information and methodologies more adaptable tools have emerged, evolving quickly alongside design workflows and technologies. Machine learning, predictive algorithms, and parametric geometries have become increasingly commonplace concepts that must be mastered to provide high-quality information and problem solving for complex problems, especially during critical project phases like conceptual massing and schematic design. It’s in these critical phases where a project’s potential is developed, making possible subsequent fulfillment. These tools require a deep understanding of the phenomena at play, as traditional assumptions may fall short in meeting current design needs. Design methods have evolved significantly alongside the newer generation of design tools, as discussed in one of the papers in this issue of SKINS.

Finally, case studies provide valuable real-world insights, measuring the effectiveness of design decisions against theoretical values. This area of study needs more attention, especially concerning operational and embodied carbon. Newer projects meeting ambitious sustainability targets could offer a wealth of data for the industry. Sadly, egregious industry practices, like the now ubiquitous non-disclosure agreements, have hobbled the knowledge-sharing and plugged the feedback loops we need to evolve our work products. FTI is working to restore these processes and provide a neutral platform for knowledge-sharing, as we are attempting to do in this issue of SKINS.

Ultimately, there’s no fooling mother nature. Every design decision, however small, can ripple through a building’s life cycle, and the negative effects often boil down to a disconnect between a building’s design choices and the requirements of its environment. Architects like Loos and Olgyay recognized this need for coherence more than half a century ago - and arguably this has always been true for centuries-old vernacular architecture. A fully glazed building in the desert is hardly a sustainable proposition because it’s incoherent with its environment, the vernacular, and climate requirements. Often, complex gadgets and high-tech materials are used to bridge problems created by short-sighted architecture in the first place. In other words, technology is often used as a band-aid instead of a boost for a project’s potential. Starting with design coherence makes the task of achieving truly resilient and sustainable buildings more manageable and economical.

I hope you find these articles as insightful and thought-provoking as I did. If you are aware of or come across other noteworthy projects with sharing, please let us know at skins@facadetectonics.org. See you soon at the FTI World Congress in Salt Lake City!

The SKINS Team

Rodrigo Borghino, Partner, The Façade Studio

Guest Editor

Mic Patterson, Facade Tectonics Institute

Executive Editor

Val Block, Facade Tectonics Institute

Associate Editor

Betsy Covington, Technoform

Content Editor

Alberto Alarcon, Kuraray

Social Media & Events Calendar Editor

Join the SKINS team! Contact us at skins@facadetectonics.org. There is work to do and fun to be had!

Please submit comments, suggestions, and articles for consideration to skins@facadetectonics.org.

Rodrigo Borghino

Partner

The Façade Studio

Send Email

Looking for something specific?

Search our extensive library.

FTI’s SKINS email is the central source for the latest in building skin trends and research.

All emails include an unsubscribe link. You may opt out at any time. See our privacy policy.